| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : U TECH

Model Number : BST-2

Certification : CE SGS ISO

Place of Origin : Jiangsu, China (Mainland)

MOQ : 1 Set/Sets

Price : discussible

Payment Terms : L/C, T/T

Supply Ability : 15 Set/Sets per Month

Delivery Time : 45 work days

Packaging Details : Wooden Case for 5L-10L-15L-20L HDPE Plastic Jerry Can Tank Container Drum Extrusion Blowing Mould /Blow Molding Machine

Material : Stainless Steel

PLC : MITSUBISHI

Control System : PLC+touch Screen

Mould Cavity : 1-2

Capacity (Kg/hr) : 50-60/KG

Operation screen : SIMENS

Fully Automatic 2L Extrusion Blow Molding Machine / Plastic Machinery

Introduction

This machine is suitable for the small bottles from 30ml upto 2Liter different sizes. You can have different options in this machine like single station, double station, single head, multi heads, view strip, single layer, multi-layers , auto-deflashing function and so on.

We will make the most suitable configuration according to your requirement in you new project.

Feature

1. Electronic control system: Japanese Mitsubishi PLC computer plus man-machine interface (Chinese or English) red paper, touch-screen operation. All process settings, changes, search, monitoring, fault diagnosis and other functions are achieved on the touch screen, no contact with the working principle, components and durable.

2. Hydraulic system: proportional pressure control, equipped with imported brand-name hydraulic components, stable and reliable.

3. Plasticizing system: efficient plasticizing mixing screw, plastic plastic to ensure adequate and uniform.

4. Speed control system: frequency control + alloy steel gear reducer, smooth speed, low noise, durable.

5. Opening and closing mode, mobile system: beam arm, three o’clock, the center of the mold clamping mode, to ensure long-term use. Clamping force balance, no deformation, and the use of translation mode body (ball linear guide), high precision, less resistance, faster.

6. Blowing needle holder: the overall angle-type blowing needle holder, stable and not shift, to ensure that products cut smooth.

Components list

COMPONENTS NAME | BRAND | ORIGIN |

PLC | MITSUBISHI | Japan |

Operation screen | SIMENS | Germany |

Parison control system | MOOG | Japan |

Inverter | MITSUBISHI | Japan |

Pneumatic parts | FESTO | Germany |

Hydraulic pump and valve | YUKEN | Japan |

Transducer | GEFRAN | Italy |

Contactor | SCHNEIDER | France |

Relay | SCHNEIDER | France |

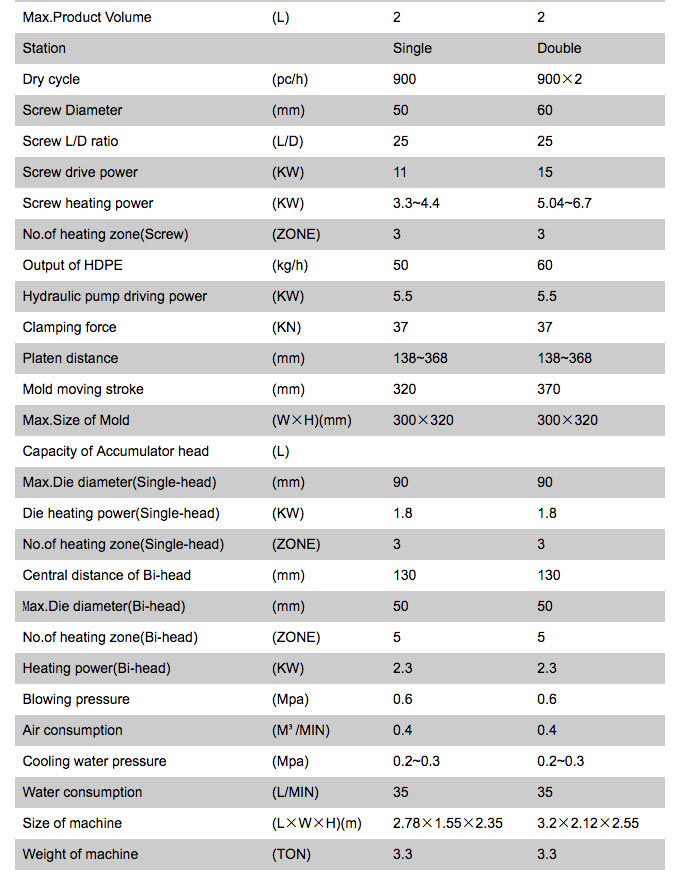

Parameter

|

|

2L Extrusion Blow Molding Machine / Fully Automatic Extrusion Moulding Machine Images |